GlassProtect Jeweller

Wireless glass break detector with a microphone

Intruders can break silence, not security

Forget about the typical problem of glass break detectors — false alarms caused by barking dogs, traffic, water splashing, and extraneous noise. GlassProtect Jeweller has a unique DualTone digital algorithm designed to minimize false alarms. The detectorʼs microphone responds only to vibrations characteristic of the glass breaking sound. You can adjust one of three sensitivity levels and run the test to check if everything works properly.

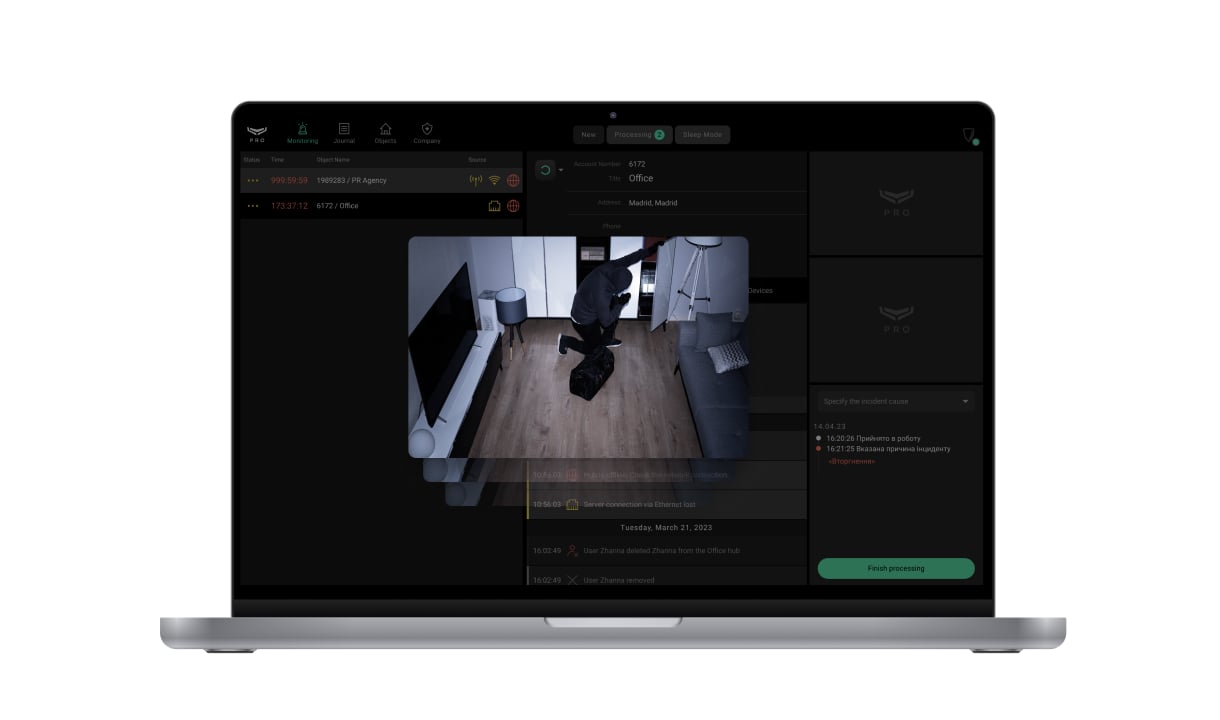

In an Ajax system, you can combine devices of all product categories: Intrusion protection, Video surveillance, Fire and life safety, or Comfort and automation. Create the system to suit your needs and manage it in a single interface.

Wherever there is a risk of intrusion

Discover future-proof hardware

Electret microphone

Pre-installed battery

Tamper against detaching the detector from the surface

Jeweller antenna

Terminals to connect a third-party NC detector

SmartBracket mounting panel

Enhanced glass break detection

GlassProtect Jeweller uses a sensitive electret microphone and the DualTone digital algorithm to detect the sound of glass breaking. To register a glass break and report an alarm, the device must detect a dull (low-frequency) sound of an impact and a ringing (high-frequency) sound of glass breaking in 1.5 seconds. This two-stage glass break detection algorithm decreases the risk of false alarms. Three sensitivity levels can be configured in the Ajax app, making the detector suitable for any object.

GlassProtect Jeweller doesn’t respond to the breaking of glass covered with shockproof, sunscreen, decorative, or any other film. To detect such glass breaking, we recommend using Superior DoorProtect Plus Fibra, DoorProtect S Plus Jeweller, or Superior DoorProtect G3 Fibra detectors with shock and tilt sensors.

Easy integration with third-party detectors

GlassProtect Jeweller has terminals for connecting a third-party wired NC detector. This allows the installer to enhance system reliability with any NC detector, whether newly installed or already in place, such as motion, opening, or vibration detectors. For example, GlassProtect Jeweller enables you to integrate an existing third-party2 opening detector into the system.

Opening detector

Vibration detector

Motion detector

Wire-free flexibility and reliable performance

Baseline devices operate without any wires, offering maximum flexibility during installation. The pre-installed CR123A battery from proven manufacturers ensures a hassle-free setup, requiring no additional steps to start operating the devices. In addition to real-time testing during battery production, Ajax Systems inspects every unit to ensure the accuracy of the battery characteristics. The battery can be easily replaced after approximately five years of autonomous operation. Its status is always accessible in the Ajax app. Users and security companies receive low battery level notifications months in advance, allowing for timely replacement without rushing.

Real-time testing during battery production

Up to 5 years of autonomous operation

Low battery level notification in advance

Jeweller

Unique wireless technology

An Ajax system uses two-way secure radio communication based on the Jeweller proprietary protocol. It provides block encryption and device authentication at each communication session with the hub to prevent sabotage, spoofing, or data theft.

Up to 1,000 m (3,250 ft) of radio communication with a hub or a range extender1

Encrypted two-way radio communication

Notifications about jamming and communication loss

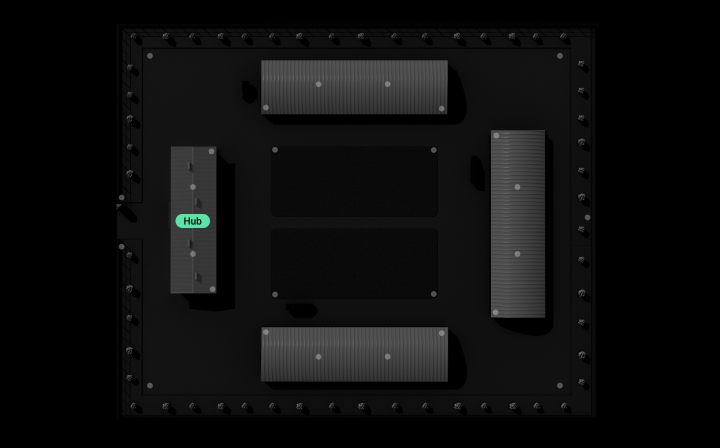

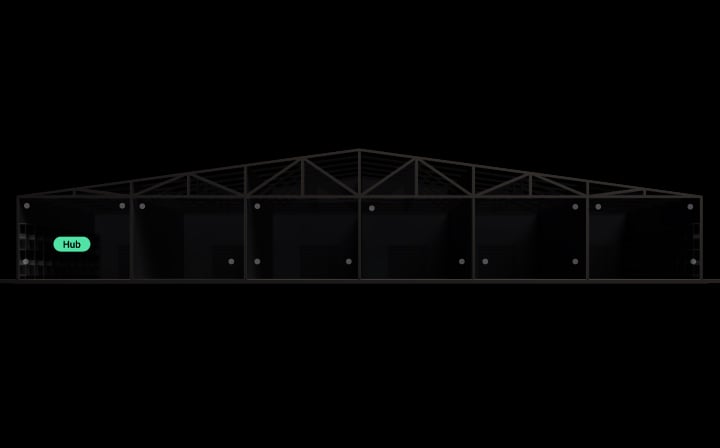

Scaled and comprehensive

ReX 2 Jeweller boosts the radio range of all Ajax devices via Jeweller and ensures stable communication even through steel and concrete via Ethernet using the wire as the additional communication channel. Up to 5 range extenders can operate within one Ajax system to expand the network twice as big, covering underground parking, basement, or metal hangar.

Up to 5 range extenders within one system

Ethernet as an alternative communication channel

System supervision

All Ajax devices perform automatic self-diagnosis and report their states to the hub. Essential parameters, such as a tamper state, communication, power supply, and sensor statuses, are continuously monitored. The Ajax Cloud server controls communication between the hub and Ajax apps, ensuring instant notifications for ARCs, security companies, and users. In case of any malfunction or communication failure, an engineer is informed immediately to provide necessary services.

Automatic device self-diagnosis with status report

Regular polling to display the current device state in apps

Instant maintenance notifications

Sabotage resistance

Effortless installation and setup

GlassProtect Jeweller is ready to operate straight out of the box. Using the SmartBracket panel, an installer can effortlessly mount the device on the wall, eliminating the need to disassemble the enclosure. Ajax apps help quickly make the device a part of the ecosystem: simply pair the device with the hub by scanning the QR code. It can always be reconfigured remotely without the need for on-site visits.

Pairing with the hub by scanning the QR code

The SmartBracket mounting panel: no need to disassemble the enclosure

Configuring and testing in mobile and desktop apps

The PRO Desktop app for macOS and Windows

In an open space.

GlassProtect Jeweller can’t power a third-party detector. The power supply for this detector should be connected separately.

Technical information

More GlassProtect models

Ajax product categories

In an Ajax system, you can combine devices of all product categories: Intrusion protection, Video surveillance, Fire and life safety, or Comfort and automation. Create the system to suit your needs and manage it in a single interface.

Wireless glass break detector for alarm system Ajax GlassProtect

The security system is designed to protect the territory from fires, leaks and intrusions. Appropriate detectors for each type of threat help prevent property damage and secure the premises. The glass breakage sensor is one such device.Glass breakage sensors are used indoors and signal burglary after the corresponding sound is recorded. Glass break detectors are installed in private premises, shops, offices, etc. Before installing a glass break detector, users should familiarize themselves with the types and features of the devices.

Classification of glass break sensors

According to the principle of work:

- Piezoelectric glass break sensors — react to mechanical impact. Annunciators activate oscillations in the glass sheet after impact. There are two types of piezoelectric sensors.

Impact sensors are equipped with additional sensitive elements triggered by the first inertial impulse. The second type of piezoelectric glass break detector detects the mechanical vibrations of the material before it breaks. The piezo element then converts the signals into an electrical impulse. Sensitive sensors are fixed on the glass surface. This sensor has limited sensitivity settings and is almost impossible to protect large glass sheets.

- Electrocontact glass break sensors — determine the integrity of the glass by mechanical control. An electrocontact type sensor is presented in the form of a thin wire in a fragile sheath or in the form of a wide strip of metal foil, which is coated with a lacquer dielectric. An electric current is passed through the conductor. When the glass surface is broken, the conductive element breaks. This technology is rarely used due to a number of disadvantages:

- Labour-intensive installation of fragile elements and the impossibility of their connection in the event of an accidental break, even by soldering.

- Not an aesthetic appearance and excessive attraction of the attention of intruders. Glass can be cut without touching the wires.

- Acoustic glass break detectors — react to the sound characteristic of broken glass. Sound sensors activate an alarm if they detect acoustic waves in the spectrum characteristic of broken glass.

Distinctive characteristics of acoustic glass break sensors:

- High speed of response to the pathogen and recognition accuracy.

- Wide range of settings and high sensitivity.

- Convenient installation and connection. Indoor installation on walls or ceiling.

Acoustic glass break sensors are the most common in alarm systems. Devices of this type have a high level of protection and the absence of false alarms for extraneous sounds.

Features of acoustic glass break sensors

Device activation algorithm:

- The sound sensor microphone receives acoustic vibrations and converts them into an electrical signal.

- The sound sensor actuators can generate several signal types depending on the model.

- Depending on the model, the sound sensor actuators can generate several signal types

The analysis of acoustic waves passes through the low-frequency and high-frequency amplitude. As a result of hitting the glass, low frequencies appear, and high frequencies are the sound of a broken sheet of glass.

Device selection and installation options

Users need to pay attention to the monitored glass sheet type, size, and thickness when choosing a sound-type glass break sensor. Most of the models are universal devices, in memory of which there is information about the most common types of glass in construction. The acoustic sensor can work with 2.5-8 mm glasses.

Please note that separate settings or specific sensor models are required for reinforced or laminated glass.

Power type. There are glass break sensors with an autonomous power source and connection to the alarm system loops. Such devices operate from 8-30 V. Wired break sensors must be installed in the interior at the design stage to install the power cable.Effective sensing distance. Users should not place the device at the maximum distance indicated by the manufacturer in the instructions since, in this case, the sensor sensitivity works at its full, and more energy is consumed.Glass break sensors are recommended to be mounted on walls or other load-bearing structures that are not subject to vibration at the height of up to 2 m. Such an arrangement of the device will prevent obstruction of the signal of the glass break detector by third-party objects and its unauthorized dismantling. When installing the device, users need to consider the presence of protective films, curtains, blinds and other elements on the glass. They can distort or make the breaking sound weak. An essential function of the glass break sensor is anti-masking, preventing sensitive sensors from being blocked.

Wireless glass break detector Ajax GlassProtect for indoor installation

The principle of operation of the glass break sensor Ajax GlassProtect

Glassbreak detector Ajax GlassProtect is a wireless device designed to detect broken glass in a protected area. The wireless sensor detects and captures low, and high-frequency glass breaking sounds with a sensitive microphone. After catching the incident, the sensor sends an alarm signal to the alarm control panel via the Jeweller secure radio channel. After a multi-stage signal analysis, the wireless detector reacts to the sound of broken glass, ignoring other loud sounds.A wireless glass break sensor is installed on the SmartBracket mount in a few minutes without disassembling the case. The GlassProtect wireless glass break detector transmits a signal via two-way radio communication, protecting the device from forgery and encrypting the transmitted information. This principle of signalling provides security alarm protection against hacking attempts. Communication is maintained at a distance of up to 2000 m to the hub control panel if there are no obstacles.The security glass break detector is compatible with wired control panels thanks to connecting the Ajax ocBridge Plus radio sensor receiver. Wireless glass break detector recognizes the pathogen at a distance of up to 9 meters. If someone tries to break the window to enter the premises, the alarm system will immediately notify users and the security company about the incident.

Installation of a glass break detector

The wireless device is ready to work out of the box. The battery is pre-installed. Connection and all settings of the wireless sensor are made in the Ajax mobile application. The glass break detector is mounted on the SmartBracket mount without disassembling the case.The wireless glass break detector is equipped with a tamper button that warns system users about an attempt to open the device or remove it from the mounting panel.